PE fiber Mooring Rope

Description

1. Product Name: Mooring Rope

2. Material: PE fiber

3. Application: Marines

4. Production Scope: The structure of mooring rope can be divided into 8-strand and 12-strand

5. Color: Customers' Requirments

6. Length: Customized

7. Certificate: DNV

8. Place of Origin: Hebei, China

9. Brand: J&L

10. Packing: Coil

11. Port: QINGDAO, SHANGHAI, TIANJIN

We can customize for you according to your requirement.

Our Advantages

Product: PE fiber mooring rope of eight-strand and twelve-strand are produced after resin treatment of the yarn with the international advanced technique. Protection sleeve can be added according to customer's requirements, which can improve the wear-resistant capacity. As to the strength, it is higher than the steel wire rope with the same diameter, but the weight is only 15% of the wire rope. Low elongationat 3.5-4.5%. Density is 0.97g/cm³, which can make sure t can float on the water. Soft, U-resistant, good bending and anti-fatigue capacity, fatigue resistance strength is 1000 times of that of steel wire rope and Nylon rope.

Application field: mooring, anchoring, lifting sling, towage, military industry, ocean oil, and ocean transportation, etc.

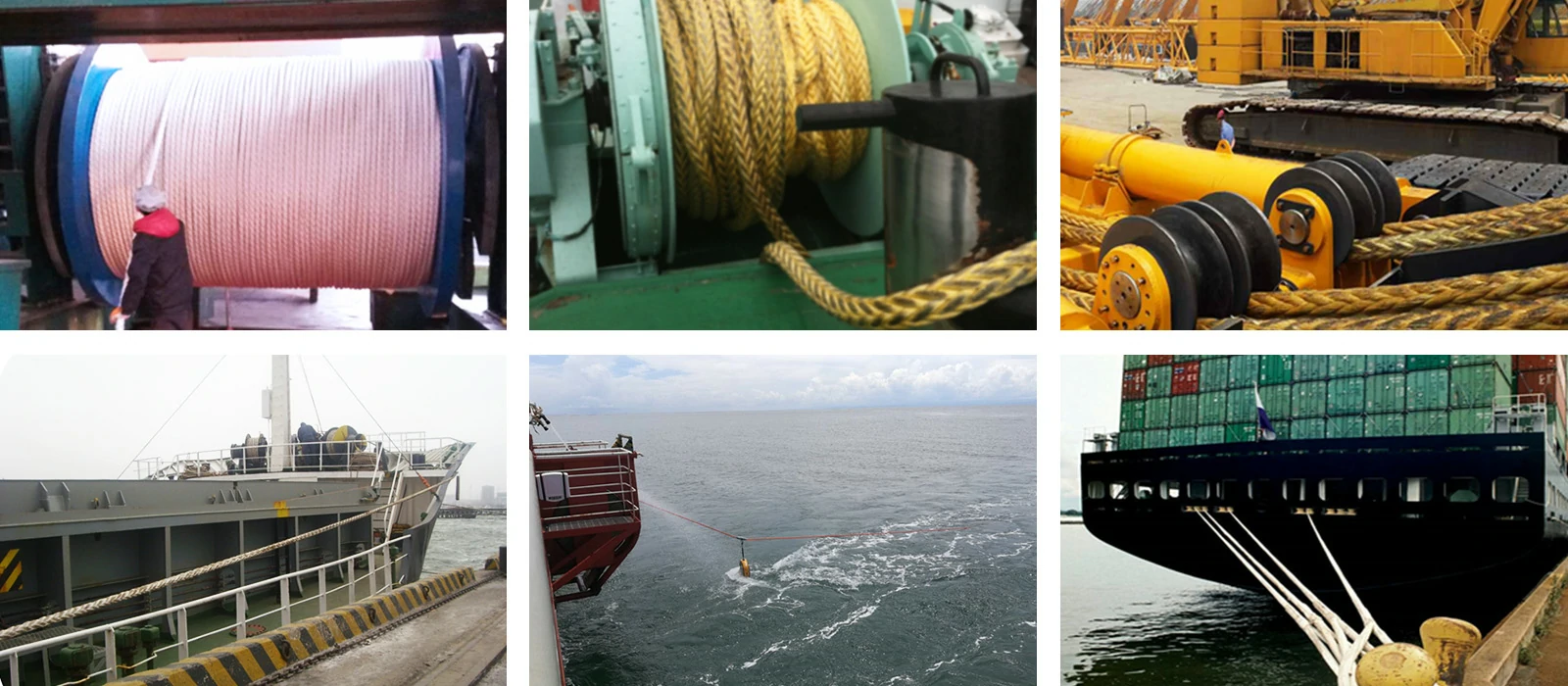

PE fiber Mooring Rope Usage

Mooring ropes are mainly used in shipping equipment, fishing industry, port operation, electric construction, oil exploration, national defense and sports goods, etc.

Application field: mooring, anchoring, lifting sling, towage, military industry, ocean oil, and ocean transportation, etc.

Specifications

| 8-Strand and 12-Strand PE fiber Mooring Rope | |||||||

|

Diameter (mm) |

Circumference (INCH) |

Linear density(Ktex) | Deviation(%) | Theoretical weight (kg/200M) |

Min.Breaking load | |

| (KN) | (Ton) | ||||||

| 20 | 2-1/2 | 232 | ±5 | 46.4 | 380 | 340 | |

| 22 | 2-3/4 | 281 | ±5 | 56.2 | 450 | 400 | |

| 24 | 3 | 331 | ±5 | 66.2 | 520 | 470 | |

| 26 | 3-1/4 | 384 | ±5 | 76.8 | 600 | 540 | |

| 28 | 3-1/2 | 445 | ±5 | 89 | 680 | 610 | |

| 30 | 3-3/4 | 506 | ±5 | 101.2 | 770 | 690 | |

| 32 | 4 | 575 | ±5 | 115 | 870 | 780 | |

| 34 | 4-1/4 | 648 | ±5 | 129.6 | 960 | 860 | |

| 36 | 4-1/2 | 720 | ±5 | 144 | 1040 | 940 | |

| 38 | 4-3/4 | 798 | ±5 | 159.6 | 1160 | 1040 | |

| 40 | 5 | 881 | ±5 | 176.2 | 1260 | 1130 | |

| 44 | 5-1/2 | 1060 | ±5 | 212 | 1460 | 1310 | |

| 48 | 6 | 1250 | ±5 | 250 | 1700 | 1530 | |

| 52 | 6-1/2 | 1460 | ±5 | 292 | 1970 | 1770 | |

| 56 | 7 | 1690 | ±5 | 338 | 2260 | 2030 | |

| 60 | 7-1/2 | 1930 | ±5 | 386 | 2530 | 2280 | |

| 64 | 8 | 2200 | ±5 | 440 | 2840 | 2560 | |

| 68 | 8-1/2 | 2480 | ±5 | 496 | 3170 | 2850 | |

| 72 | 9 | 2780 | ±5 | 556 | 3520 | 3170 | |

| 76 | 9-1/2 | 3090 | ±5 | 618 | 3890 | 3500 | |

| 80 | 10 | 3430 | ±5 | 686 | 4300 | 3870 | |

| 88 | 11 | 4170 | ±5 | 834 | 5200 | 4680 | |

| 96 | 12 | 4970 | ±5 | 994 | 6180 | 5560 | |

| 104 | 13 | 5800 | ±5 | 1160 | 7180 | 6470 | |

| 112 | 14 | 6730 | ±5 | 1346 | 8280 | 7460 | |

| 120 | 15 | 7720 | ±5 | 1544 | 9440 | 8500 | |

| 128 | 16 | 8790 | ±5 | 1758 | 10670 | 9610 | |

| 136 | 17 | 9920 | ±5 | 1984 | 11930 | 10750 | |

| 140 | 17-1/2 | 10510 | ±5 | 2102 | 12560 | 11320 | |

Package

JULI standard export package:Customized packaging according to customer needs

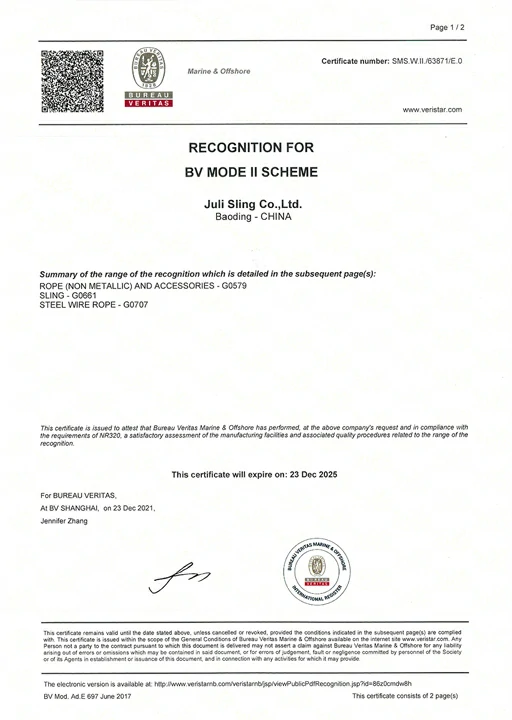

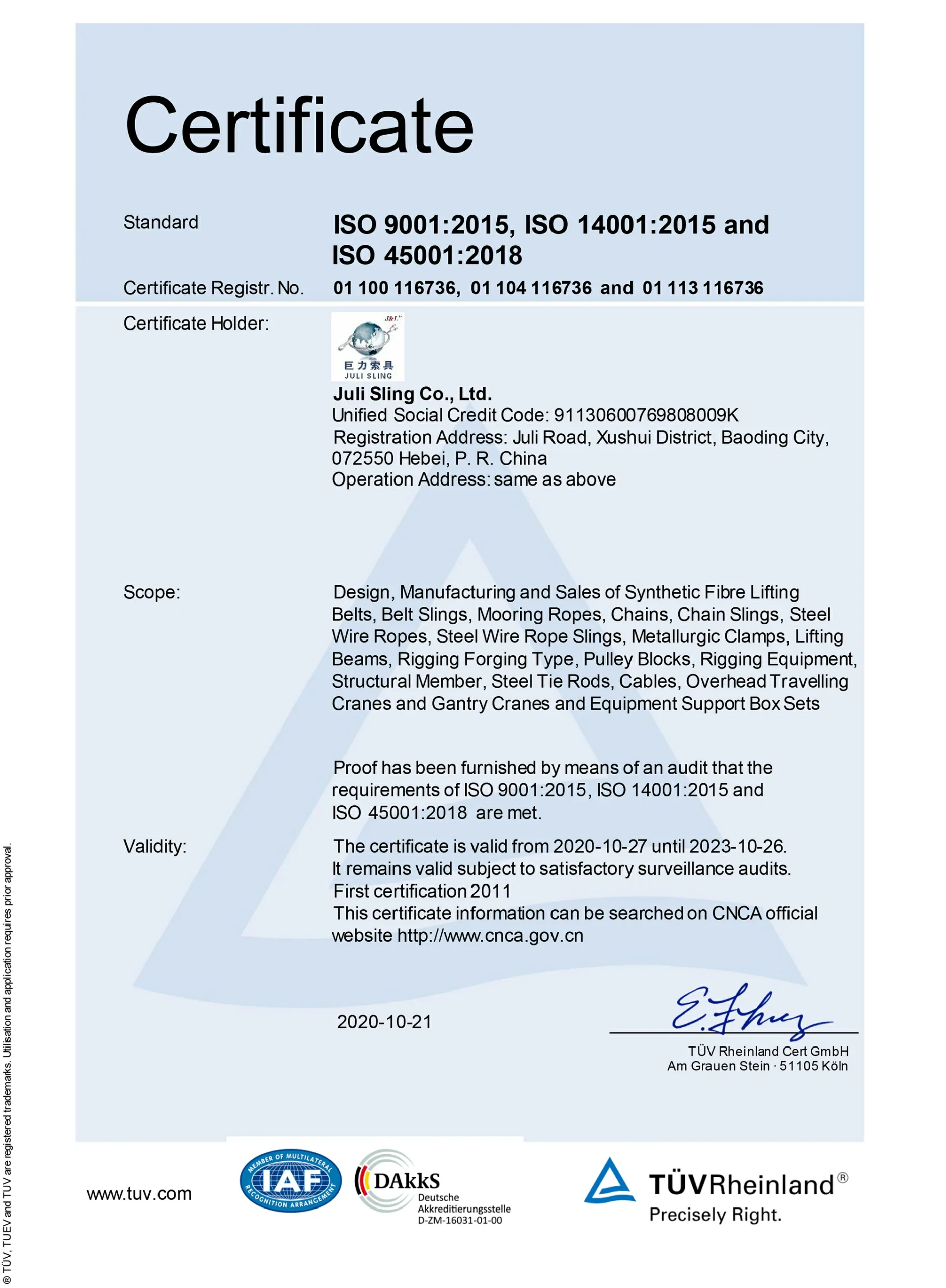

Certifications

DNV▪GL ISO CNAS

Production Process

Production Scope: The structure of mooring rope can be divided into 3-strand, 6-strand, 8-strand and 12-strand. The raw material includes: polypropylene, polyester, nylon, Super high tensile strength polyethylene, aramid fibre and synthetic fibre. Diameter scope: Ф6mm ~ Ф140mm are available.

Export Cases

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.